There are several kinds of aluminum alloy surface treatment

There are several kinds of aluminum alloy surface treatment

1. Surface grinding and polishing

Using mechanical, chemical or electrochemical methods to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. The polishing process is mainly divided into: mechanical polishing, chemical polishing, electrolytic polishing. The aluminum parts are mechanically polished.

After electrolytic polishing, it can be close to the mirror effect of stainless steel, giving people a high-end, simple and fashionable feeling.

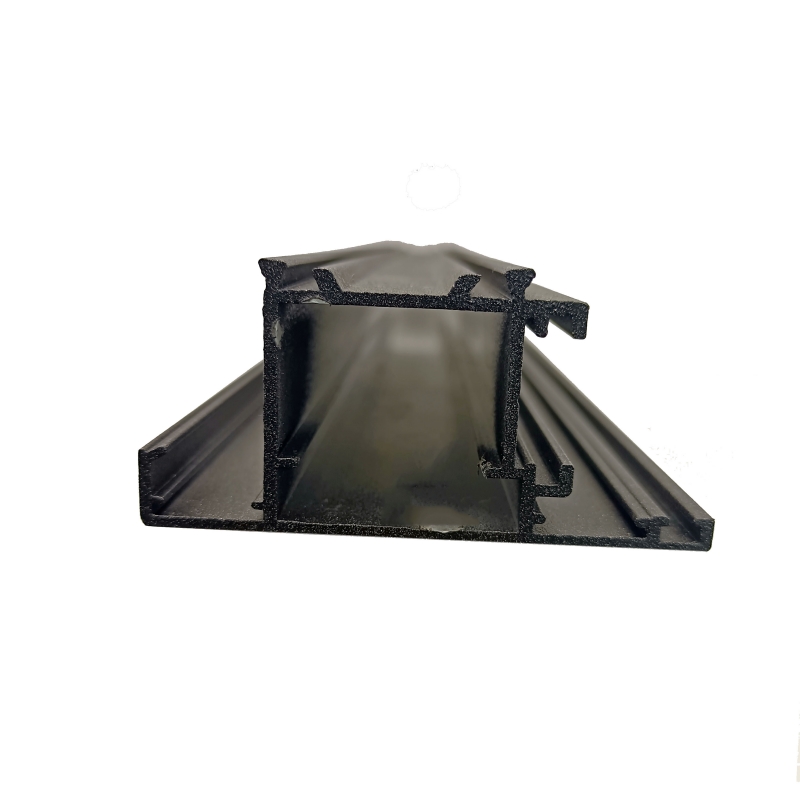

2. Surface blasting and shot blasting

The process of cleaning and roughening metal surfaces using the impact of high-speed sand flow.

This surface treatment can make the surface of the workpiece obtain a certain degree of cleanliness and different roughness, and improve the mechanical properties of the surface of the workpiece.

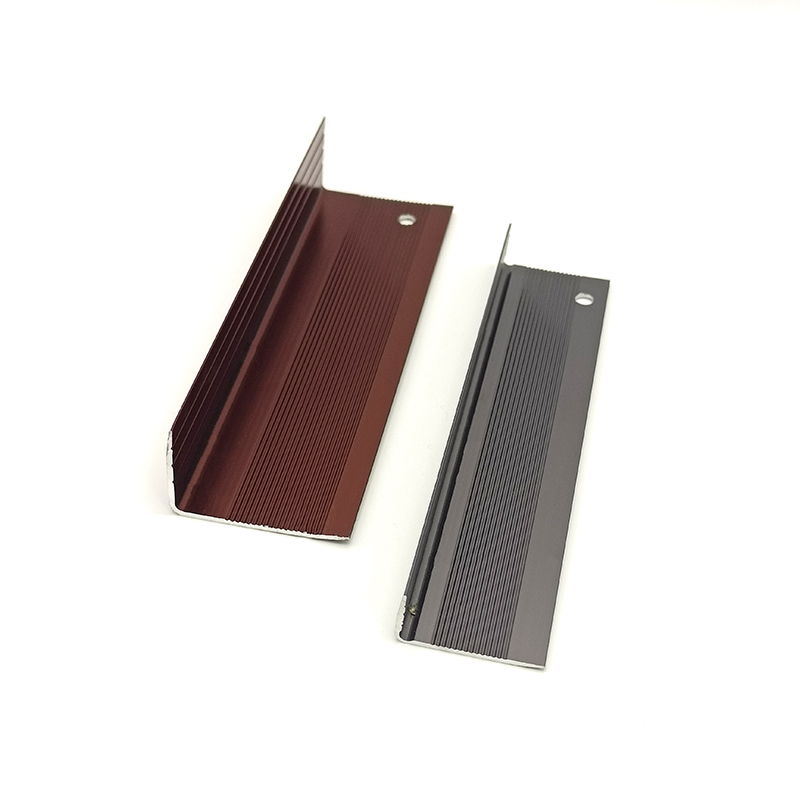

3. Surface drawing treatment

Metal wire drawing is the manufacturing process of repeatedly scraping an aluminum sheet out of lines with sandpaper.

Drawing can be divided into straight drawing, random drawing, spiral drawing, thread drawing. The metal wire drawing process can clearly show every tiny silk mark, so that the metal matte has a fine luster, and it has both a sense of fashion and technology.